Maintaining Advanced Driver Assistance Systems for Consistent Operation

Advanced Driver Assistance Systems (ADAS) rely on sensors, cameras, and software to support driving tasks. Consistent operation depends on regular maintenance, targeted inspections, and accurate diagnostics. This article explains practical steps owners and technicians can take to preserve ADAS performance through upkeep of tires, battery and charging systems, telematics, and physical inspections.

How does maintenance affect ADAS reliability?

Routine maintenance is central to reliable ADAS performance. Systems such as lane assist, adaptive cruise, and automatic emergency braking depend on clear sensor fields and properly calibrated components. Simple maintenance tasks — keeping windshields and sensors clean, replacing worn wiper blades, and ensuring body panels and mounts are intact — reduce false alerts and missed detections. Preventive maintenance schedules that include ADAS checks can identify drift or degradation early, keeping software and hardware aligned with manufacturer specifications and preserving safety and accuracy over time.

How do diagnostics support ADAS accuracy?

Diagnostics tools read sensor health, error codes, and software status to verify ADAS readiness. Professional scan tools and factory-level diagnostic equipment can reveal calibration faults in cameras, radar, and ultrasonic sensors. After any collision repair, sensor replacement, or windshield change, a diagnostics check should confirm that no faults remain and that firmware is current. Regular diagnostics also detect intermittent faults such as wiring issues or water intrusion, enabling targeted repairs before those faults degrade system accuracy during critical events.

Why do tires, alignment, and suspension matter?

Tire condition, alignment, and suspension geometry directly influence ADAS sensor interpretation and vehicle dynamics. Uneven tires or incorrect alignment alter vehicle tracking and steering responses, which can confuse lane-keeping and lane-centering algorithms. Similarly, worn suspension components change ride height and pitch, affecting radar and camera mounting angles. Maintaining correct tire pressure, rotating tires, replacing worn shocks or struts, and performing wheel alignment preserves the physical baseline ADAS systems rely on for consistent measurements and predictable control behavior.

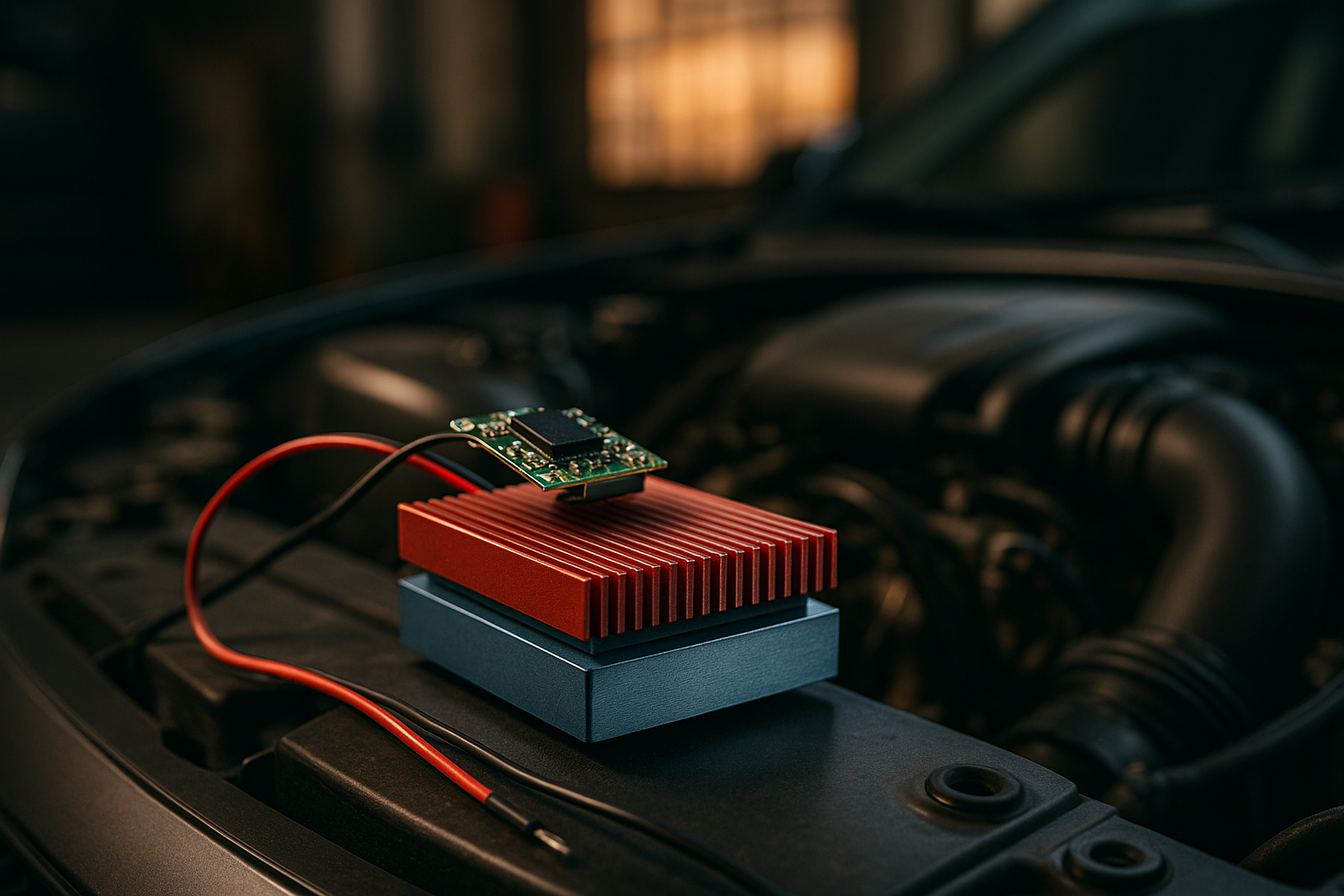

What role do battery, charging, and fuel systems play?

Power quality and availability are essential for continuous ADAS operation. A weak battery or poor charging system can cause voltage drops that affect sensors and electronic control units, triggering errors or temporary shutdowns. For hybrid and electric vehicles, battery health ties directly to high-voltage systems that supply sensors and actuators; degraded modules can lead to limited functionality. Regular battery inspection, charging system testing, and attention to fuel system integrity on combustion vehicles help ensure ADAS modules receive stable power for reliable sensing and control.

How do telematics and regular inspection fit into upkeep?

Telematics platforms and periodic inspections provide data and structured checks that support ADAS upkeep. Telematics can flag recurring faults, log sensor disruptions, and report software updates pushed by manufacturers. Scheduled inspections should include camera and radar calibration checks, lens cleaning, wiring inspections, and firmware verification. Combining telematics data with hands-on inspections helps technicians prioritize repairs, track trends such as recurring calibration drift, and ensure inspection routines address both mechanical and electronic aspects of system health.

How does towing or physical damage affect ADAS safety?

Towing, impacts, and body repairs often disturb sensor alignment, mounts, and wiring, degrading ADAS safety. Even seemingly minor bumper or windshield work can shift camera or radar position enough to impair detection zones. After towing or any collision, technicians should inspect sensor housings, connectors, and mounting points, and complete manufacturer-recommended recalibration. Physical damage can also introduce water intrusion or connector corrosion that causes intermittent diagnostics faults; thorough inspection and testing reduce the risk that ADAS features perform unpredictably when needed most.

Conclusion Consistent ADAS operation requires attention to both traditional vehicle maintenance and modern electronic diagnostics. Maintaining tires, alignment, suspension, battery and charging systems, and performing regular inspections and diagnostics helps preserve sensor accuracy and software reliability. Integrating telematics insights and post-repair calibration into routine service cycles supports long-term ADAS performance and predictable safety outcomes without relying on ad hoc fixes.